- #Printable metric tap drill chart pdf#

- #Printable metric tap drill chart series#

- #Printable metric tap drill chart free#

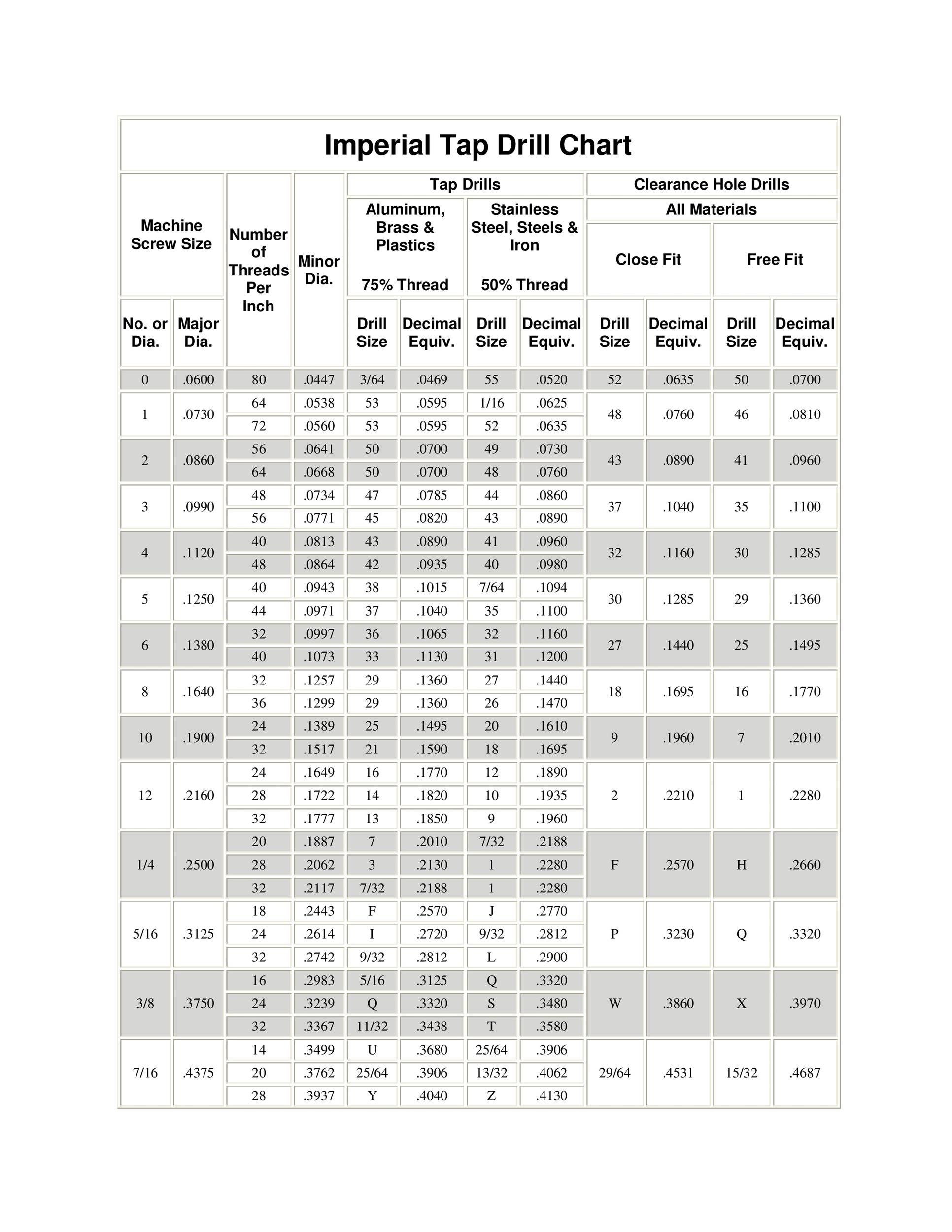

Imagine the fully formed internal thread. To know which drill bit size is right for your particular tapping application, you need to consider what thread percentage you want when you’re done tapping.

How can that be? Well, it’s actually pretty simple. Anytime you see just one size being recommended, you know you can do better–one size does not fit all when it comes to tapping. The same is true of the size recommended on the tap and even the recommended size from the tap manufacturer. Moreover, the size recommended in most drill bit size charts is very often not the best size to use. Let’s start with an important fact–there isn’t just one drill bit size to use for a given tap size. Newsflash: There Isn’t Just One Drill Bit Size for a Tap But in this age of computers and the Internet, you can do better. If it has information on which twist drill size to use for tapping, so much the better. Make no mistake: having a good drill bit size chart (sometimes called a “drill index”) is a very handy thing indeed to have around. What’s better than a drill bit size chart?

#Printable metric tap drill chart free#

Let us help, and BTW, it’s completely free too!

#Printable metric tap drill chart pdf#

If you just want a simple tap drill chart in Metric and Imperial sizes, or a pdf you can print and post in your workshop, scroll on down.īut, before you do, wouldn’t you like to hear about something that’s much better in every way? Something that’ll make it much less likely you’ll break a tap? Something a little more modern than a simple chart? Aircraft-length drills are extended length drill bits that are manufactured in fixed length such as 4, 6, 8, 12, 18, 24-inch bits, rather than proportional lengths.Tap Drill Chart: Metric & Imperial Size.They are used primarily in machinist workshops for screw machinesand are not usually available in hardware stores. Screw-machine-length drills arethe shortest available standard sized bits.Jobber-length drill bits are the most common, with a length somewhere between 9 to 14 times the diameter.The length of drill bits vary depending on their application. The drill size chart below contains all commonly used centre drill bit sizes. They are commonly used to drill lathe centres and spotting drills, i.e.marking holes to guide twist drilling. These specialist drill bits are used for drilling centre holes at two different angles, 60 degrees and 90 degrees. The drill size chart below gives fractional sizes and their metric conversions up to 1 inch. reduced as far as possible, so 2/64 becomes 1/32 for instance. The fractions used are always in their simplest form, i.e. Most commonly used in the US, but can still be found occasionally in the UK, these imperial measurement drill bits come in 1/64 inch increments. Gaugeįractional drill bits are definedby the ANSI B94.11M-1979 standard. The drill size chart below contains imperial and metric drill bit diameter measurements for all number and letter gauges. Most other countries, especially in Europe, have abandoned them entirely in favour of metric systems. They are also seen in the UK to a lesser degree, having been largely replaced by metric sizes. They are loosely based on the Stubs Steel Wire Gauge, with gauge sizes that are similar (but not entirely identical) to that system.Īlthough they originated in the 19 thcentury, these gauges are still commonly used in the U.S.

Number and letter gauges do not follow a formula or standard increments.

#Printable metric tap drill chart series#

The R5 series uses a factor of 1.58 and contains the following sizes: M2.5, M4, M6, M10, M16 and M24.Other bit types, such as Forstner bits, will contain different size cutting surfaces.Īnother example of a metric set of drill sizes is the Renard series, which uses a simple factor to determine the diameter: Please note that BS 328 sizing only applies to twist drill bits. There are a variety of standards used to define drill sizes, the most common one in the UK is the British Standard BS 328 set which includes twist drill bit sizes between 0.2 mm and 25 mm.īS 328 drill sizes are defined as shown in the drill size chart below: ø0.2 to 0.98 mm: Metric drill sizes are used primarily in Europe and use metric units to measure the drill bit diameter. To get an accurate measurement, use Vernier callipers, but be aware that depending on the quality of the drill bit, there could be a tolerance error of between 5 and 15 thousandths of a unit.

To measure the diameter of a drill bit, it’s best to measure the cutting edge rather than the shank (the shank is the part that is held by the drill chuck).

0 kommentar(er)

0 kommentar(er)